Progressive Dies

Progressive Dies & In-House Tryout | High-Quality Stamping Dies

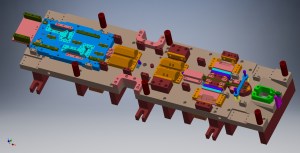

Precision-Engineered Progressive Dies for Superior Performance

B&H Tool Works specializes in designing and manufacturing high-quality Class A progressive dies for a wide range of industries, including automotive, home appliances, and government contracting. With over 30 years of experience, we deliver precision-engineered stamping solutions that meet and exceed industry standards. Our expertise ensures that every die we produce adheres to the highest levels of durability, efficiency, and precision.

Why Choose B&H Tool Works for Progressive Dies?

- Turnkey Solutions – From initial concept to PPAP approval, we provide end-to-end progressive die solutions.

- Rapid Development – Quick trim-line development and stock strip creation with in-house laser technology.

- Complete In-House Tryout – Die tryout capabilities up to 700 tons ensure optimal performance before production.

- ISO 9001:2015 Certified – Ensuring quality and consistency in every project.

- Advanced Technology – CAD, laser cutting, wire EDM, and CNC machining for superior accuracy and efficiency.

- Trusted Tier 2 Supplier – Providing progressive tooling for major automotive manufacturers.

- Cost-Effective Solutions – By utilizing efficient production methods, we help you reduce costs without compromising quality.

What is a Progressive Die?

A progressive die is a specialized stamping tool that incrementally forms metal parts as a steel coil passes through multiple die stations. Each press stroke progressively shapes the part until a fully formed component is ejected at the final stage. This method is widely used to manufacture small metal brackets and complex sheet metal parts efficiently.

Progressive dies are ideal for high-volume production runs, offering:

- Consistent quality with precise, repeatable results.

- Reduced waste by optimizing material usage.

- Streamlined manufacturing by eliminating the need for multiple press operations.

- Improved accuracy for complex part geometries.

The versatility of progressive dies allows manufacturers to create intricate components with minimal material usage, making them an environmentally friendly and cost-efficient choice.

Comprehensive In-House Die Tryout Capabilities

Our advanced in-house tryout facility allows us to thoroughly test and refine dies before delivery. We have multiple presses to accommodate varying specifications:

- 110 Ton OBI/Hand Transfer Bliss – Bed size: 42” x 27”

- 400 Ton S.S./Progressive W&W – Bed size: 72” x 48”

- 500 Ton S.S./Progressive Verson – Bed size: 132” x 48”

- 700 Ton Aida MCX-S2-6300 – Bed size: 143” x 59”

- 600 Ton Niagra – Bed size: 156” x 60”

With these extensive capabilities, we ensure that each die meets stringent quality standards, improving production efficiency and reducing downtime for our clients. Our meticulous testing process guarantees that your progressive die is ready for full-scale production with minimal adjustments required.

State-of-the-Art Engineering & Design

B&H Tool Works leverages the latest engineering software and file formats, including:

- AutoCAD, Inventor, Catia, UGS NX

- IGES, DXF, SolidWorks, Pro/Engineer, STEP, and ParaSolid

This ensures seamless integration with your existing designs and production requirements. Our engineering team works closely with clients to develop optimized die designs that enhance manufacturability and durability.

By utilizing cutting-edge simulation tools, we can:

- Predict die performance before production.

- Reduce errors and minimize costly rework.

- Continuously refine designs based on customer feedback.

Our engineers ensure that each progressive die aligns with specific production goals and industry standards.

Partner with B&H Tool Works for Your Progressive Die Needs

When you choose B&H Tool Works, you’re investing in:

- Precision – High-quality progressive dies with tight tolerances.

- Reliability – Durable dies built to withstand high-volume production.

- Efficiency – Streamlined processes for faster turnaround times.

Our commitment to quality and innovation makes us a trusted partner for manufacturers seeking high-performance progressive dies. Whether you need new tooling, modifications, or repairs, B&H Tool Works has the expertise and equipment to meet your requirements.

Get in Touch Today!

Contact us to discuss your progressive die project and discover how we can help streamline your manufacturing process.

[Call or Request a Quote Now!]